Tungsten electrode is a critical component in Tungsten Inert Gas (TIG) welding, which is a popular welding method used in various industries, including aerospace, automotive, and construction. In this article, we will discuss the types, uses, and colors of tungsten electrodes.

Types of Tungsten Electrodes

There are four types of tungsten electrodes commonly used in TIG welding, including pure tungsten, thoriated tungsten, ceriated tungsten, and lanthanated tungsten. Pure tungsten electrode is the most basic type, and it is suitable for welding aluminum and magnesium alloys. Thoriated tungsten electrodes contain thorium oxide, which improves their durability and performance. They are suitable for welding steel, stainless steel, and nickel alloys. Ceriated tungsten electrodes contain cerium oxide, which provides better arc stability and lower burn-off rate. They are suitable for welding non-ferrous metals and alloys. Lanthanated tungsten electrodes contain lanthanum oxide, which provides high-quality arc performance and longer electrode life. They are suitable for welding aluminum alloys, magnesium alloys, and non-ferrous metals.

Uses of Tungsten Electrodes

Tungsten electrodes are used in TIG welding, which is a precise and versatile welding method that can be used to weld various materials, including steel, stainless steel, aluminum, titanium, and copper alloys. TIG welding is widely used in the aerospace industry to weld aircraft parts, such as engine components, landing gear, and structural components. It is also used in the automotive industry to weld exhaust systems, suspension components, and body panels. TIG welding is also used in the construction industry to weld pipelines, tanks, and other metal structures.

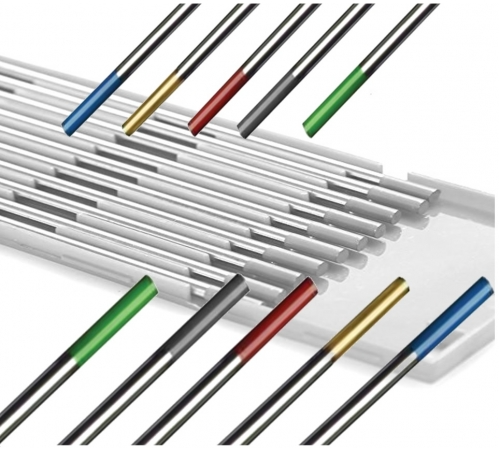

Colors of Tungsten Electrodes

Tungsten electrodes are available in different colors, which indicate their type and composition. Pure tungsten electrodes are green, thoriated tungsten electrodes are red, ceriated tungsten electrodes are orange, and lanthanated tungsten electrodes are blue. The color-coding helps welders to identify the type of electrode they are using and avoid cross-contamination.

Conclusion

Tungsten electrodes are a critical component in TIG welding, which is a popular welding method used in various industries. There are four types of tungsten electrodes commonly used in TIG welding, including pure tungsten, thoriated tungsten, ceriated tungsten, and lanthanated tungsten. Each type of electrode has its unique properties and is suitable for welding different materials. The colors of tungsten electrodes indicate their type and composition, which helps welders to identify them and avoid cross-contamination.