The welding machine for welding rod refers to the operation completed by the interaction between the welding rod and the welding equipment installed on the welding rod welding machine. Welding current and voltage are likely to change, which requires the welding machine to adjust. The welding current refers to the heat generated by heating to melt the electrode to complete the formation of the weld; The welding voltage refers to the temperature cooled from the molten pool to below the melting point. The principle of welding repair is the same as that of mechanical and chemical repair methods, and it can only be realized with the help of certain tools. Different spot welding methods are mainly completed by the interaction between the electrode and the weldment, so it can also be considered that spot welding is to weld two parts together to form a weld to complete the repair task.

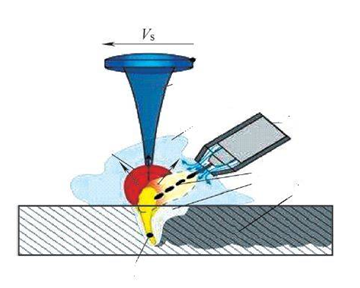

Spot welding can be operated in two ways: one method is to heat the two parts to reach the melting point within a certain period of time, and weld the workpieces together; The other method is to use special equipment for welding, such as surfacing welding, arc welding. Both surfacing welding and arc surfacing welding require a stable and sufficiently large working current, and the current must be evenly distributed. In spot welding, a relatively large welding speed is generally used to ensure the temperature of the molten pool and the quality of the weld. Arc surfacing welding usually uses a lower welding speed and a smaller welding current to complete a surfacing welding, which can ensure that the quality of the joint is not affected, but the welding seam is easy to burn due to the high temperature of the weld metal.

- The lead wire of the welding rod must be correct, otherwise it will cause poor welding.

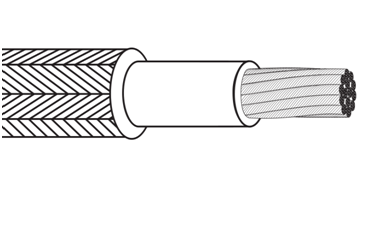

(1) The lead-out wire of the welding rod should have sufficient length, which should be 3-5 meters, and the ratio of its cross-sectional area to the diameter of the welding rod should not be less than 1/2.

(2) Each welding torch should have 6-8 lead-out wires, and the end of each joint should be perpendicular to each other.

(3) Each electrode should have a suitable lead position, and the ratio of its cross-sectional area to the diameter of the weldment should not be less than 1/2.

(4) When the welding current is too large, the arc current should be appropriately reduced to prevent the welding rod from deforming and causing poor welding quality.

- The welding rod must be placed vertically into the weld of the workpiece, and it must be placed straight, without tilting or chamfering (when the tilt angle is less than 20°).

The electrode should be perpendicular to the weld seam of the workpiece to be welded. During the welding process, the electrode can slide on the surface of the weldment. . Since the welding rod is generally placed on one side of the weld for welding during spot welding repairs, two electrodes are generally used to complete the welding of the weld, so when the side of the weld is close to the welded position Only then can welding be carried out.

(Note: If spot welding or convex welding is used, the welding current generally does not exceed 50 A. If concave welding is used, a larger current must be used to prevent spatter to ensure sufficient nugget formation. Penetration.)

- The size of the welding current should be appropriate, which can generally be determined according to the size and structural characteristics of the workpiece.

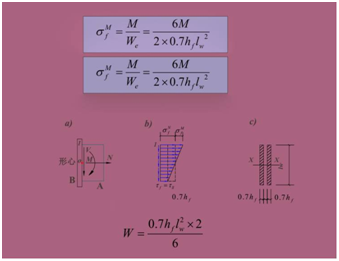

If a smaller welding current is used, the penetration depth can be increased. As the penetration increases, a larger weld width can be obtained; if the weld width decreases, the tensile strength of the weld will also decrease. Therefore, the current size can be determined according to the characteristics of the welding structure.

- When the lead-out line of the electrode is perpendicular to the weld seam, the current size should also be appropriate.

The diameter of the welding rod is mainly determined according to the size of the welding current and the welding speed. The electrode welding machine is mainly composed of multiple welding machines. When the welding machine is working, the corresponding equipment can be configured according to the welding needs. At present, the three types of welding machines commonly used are full penetration welding machines and filler metal welding furnaces.

- The welding current of the electrode must be proportional to the penetration depth, and it should be cooled in time after penetration.

The welding current of the electrode should be determined according to the size, material and welding process requirements of the weldment. ?The quality of welding repair has a great influence on the mechanical properties of the repaired parts, so the welding rod and welding machine are required to have sufficient stability, and parameters such as the width of the welding rod, the distance between the welding rods and the welding speed must be determined according to the material, thickness and size of the weldment . ?Welding equipment and electrodes must be coordinated and coordinated to ensure that the workpiece is welded in a wide or thick area for multiple passes, and the edges of the welds must be neat and beautiful.