Thorium-Tungsten Electrode is widely used as an additive Oxide electrode, having much more advanced comprehensive welding performance than the properties of pure tungsten electrode and other oxide electrodes .. It can not be replaced by other oxide electrodes during the long using process. It can be operated easily. Has a high current load and produces arc easily and steadily. In addition. The gap of the breaking arc is big. Lloss less and life longer. It has higher re-crystallizing temperature. Better conductivity and mechanical cutting property. Now. Thorium-Tungsten Electrode is widely used in welding carbon steel..stainless, nickel alloy and titanium metal. lt becomes the first selection material for high quality welding.

WT20 is the most used, WT20 welding stainless steel is the best, welding life is long, WL15 it is not radioactive, now European and the American conuntries prefer to use this.

Compared with pure tungsten materials,Thorium tungsten has the following characteristics:

* Lower electronic function * Higher crystallization temperature * Better conductivity * Good mechanical cutting performance.

Tantalum tungsten electrode A commonly used tungsten electrode material, which has superior soldering properties than pure tungsten, is widely used in the field of direct current welding.

The thorium tungsten electrode is easy to operate and works well even under overload current.

Even so, people are gradually turning their attention to other types of tungsten electrodes, such as tungsten germanium and tungsten germanium, not only because they show excellent performance in most applications, but also because they have no radiation. hurt. Due to the small amount of radiation generated by yttrium oxide in the tantalum tungsten electrode, some welders are reluctant to approach them.

Be sure to maintain a good ventilation environment when soldering with tantalum tungsten electrodes. Dispose of the solder joints properly.

package

10 / plastic box, length is 150mm or 175mm, 1000 per carton.

Yield

The total consumption of tungsten electrodes in the world reaches 1600t per year, and the market demand is still growing with the development of the economy. The annual total output of tungsten electrodes in China accounts for about 3/4 of the world’s tungsten electrode production. The annual output of tungsten electrodes in China has been growing steadily, and production has increased significantly since 2005, reaching 1200 tons in 2009.

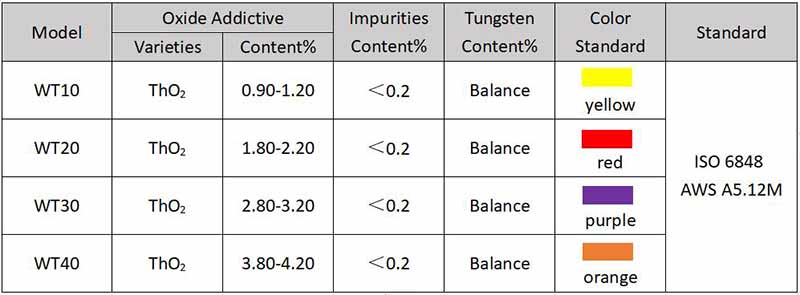

Technical Data